Northumbria expands results day support for students

Northumbria University is expanding and enhancing the support it provides to students receiving…

International

Northumbria’s global footprint touches every continent across the world, through our global partnerships across 17 institutions in 10 countries, to our 277,000 strong alumni community and 150 recruitment partners – we prepare our students for the challenges of tomorrow. Discover more about how to join Northumbria’s global family or our partnerships.

View our Global FootprintBusiness

The world is changing faster than ever before. The future is there to be won by organisations who find ways to turn today's possibilities into tomorrows competitive edge. In a connected world, collaboration can be the key to success.

More on our Business ServicesResearch

Northumbria is a research-rich, business-focused, professional university with a global reputation for academic quality. We conduct ground-breaking research that is responsive to the science & technology, health & well being, economic and social and arts & cultural needs for the communities

Discover more about our ResearchAlumni

Northumbria University is renowned for the calibre of its business-ready graduates. Our alumni network has over 253,000 graduates based in 178 countries worldwide in a range of sectors, our alumni are making a real impact on the world.

Our AlumniWhy do beers taste so different? Northumbria fermentation specialist and expert brewer explains all.

St John Usher

Brewers and alcoholic beverage producers are always looking for new products to entice the public to try their products. The key to these products, as with many foods and drinks are new flavours. When it comes to beers the volatile components associated with the product come from 3 principal areas. Firstly, the types and percentages of brewing malts used in the recipe, secondly the strain of hops added into the boil, which contribute not only bitterness but many different hop aromas.

Lastly, and most interestingly for those of us with a microbiological interest, is the yeast that is used to ferment out the wort. There are two main strains that are used in brewing - Saccharomyces cerevisiae for ales and Saccharomyces pastorianus for lagers. There are many different strains used around the world in many breweries, producing myriad beers and lagers.

However, it not only the strain of yeast that matters in terms of flavours produced in the final product, but also the fermentation conditions – temperature, inoculation levels and sugar levels,

So, as a new crop of Masters students enter the laboratories at Northumbria to undertake their projects, a group of them will be working with Dr St. John Usher, who has a research interest in beer and fermentation.

The group will be investigating the volatile components of fermentations set up in the laboratory, using a highly sensitive instrument called a Gas Chromatograph – Mass Spectrometer. This instrument allows the separation, identification and quantification of volatile compounds present in all sorts of mixtures, including alcoholic beverages.

The students will investigate the effects of conducting fermentation of ale type worts and apple juice, with a number of yeast strains - some isolated from locally grown wild fruits, such as Crab apples, eating apples and pears. The investigators will also look into what happens to the volatile components in beers and ciders, when a range of fermentation temperatures, sugar concentrations and inoculation levels are used in the fermentations.

It is believed that changing the fermentation parameters, along with using novel yeast isolates, may produce novel volatile profiles in the final products. It is hoped that altering the mentioned fermentation parameters, will introduce flavours such as ethyl butanoate, hexyl butanoate, ethyl hexanoate and hexyl hexanoate (all common in pears, cherries and passion fruits) as well as a range of furanones (common in strawberries, pineapples and mangos) into the final products, potentially leading to opportunities to develop new commercial products.

Watch this space!!

Please drink responsibly.

Northumbria University is expanding and enhancing the support it provides to students receiving…

With the global population expected to reach 10 billion by 2050 and crop yields declining annually,…

An Assistant Professor at Northumbria University won the Royal Society of Chemistry’s Award…

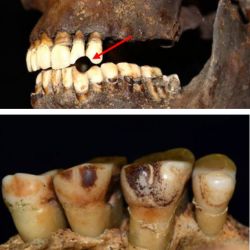

Researchers from Northumbria University have discovered that smokers have tell-tale signs of…

Northumbria University has been named Higher Education Institution of the Year at a prestigious…

Two biomedical sciences researchers from Northumbria University have been awarded grants to…

The Spring 2025 edition of Northumbria University’s newspaper is available to collect on campus…

Scientists have discovered that flies can demonstrate play-like behaviour – the first time…